Beyond the fragmented supply chain

(page 361)

In

what ways have new cooperative frameworks aided supply-chain

strategies in serving customers more quickly and with greater

responsiveness to changing demand, despite growing

inter-nationalization? Give examples.

|

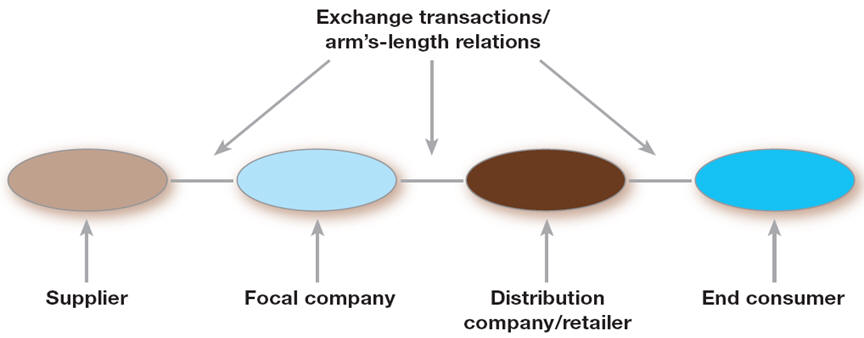

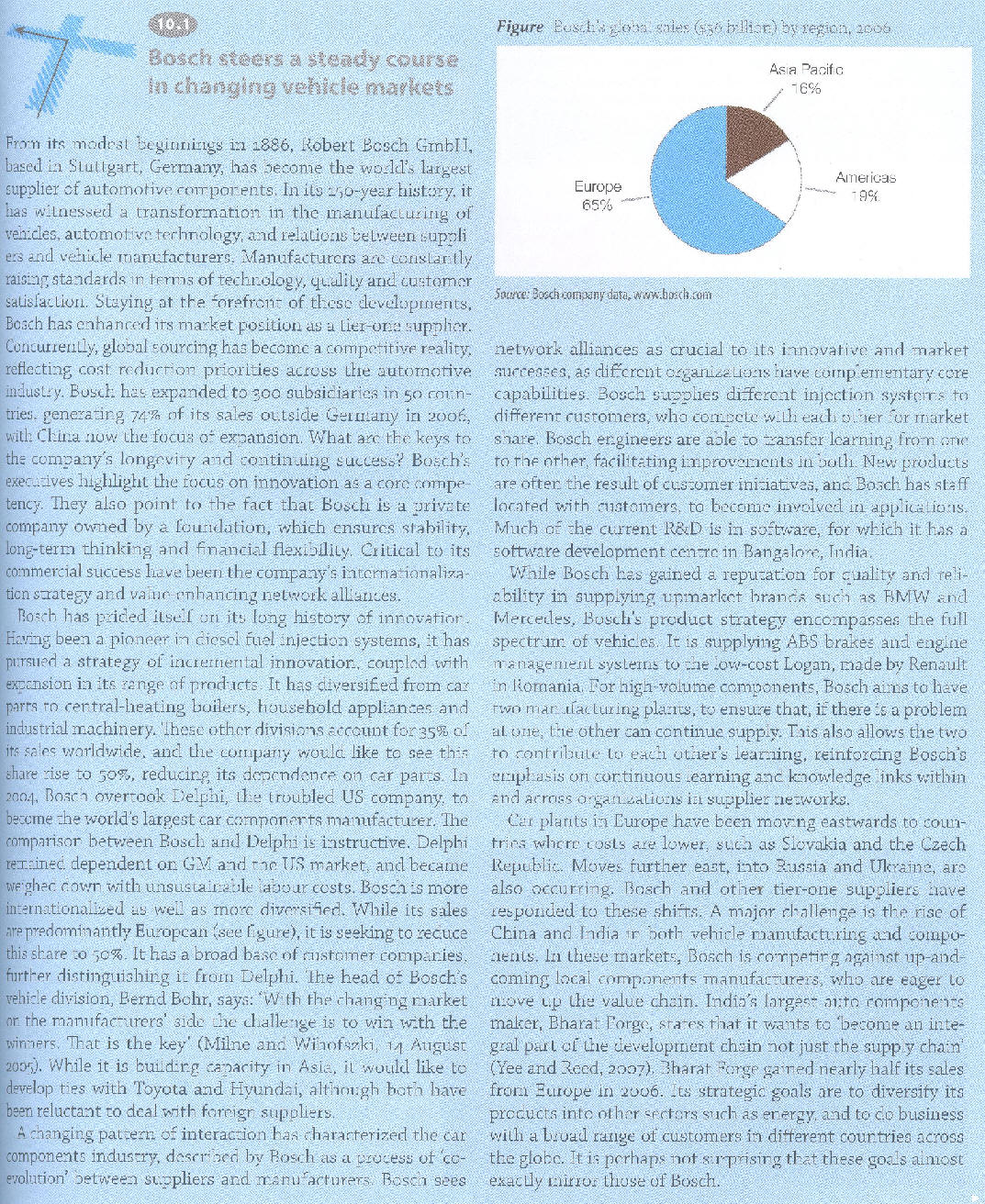

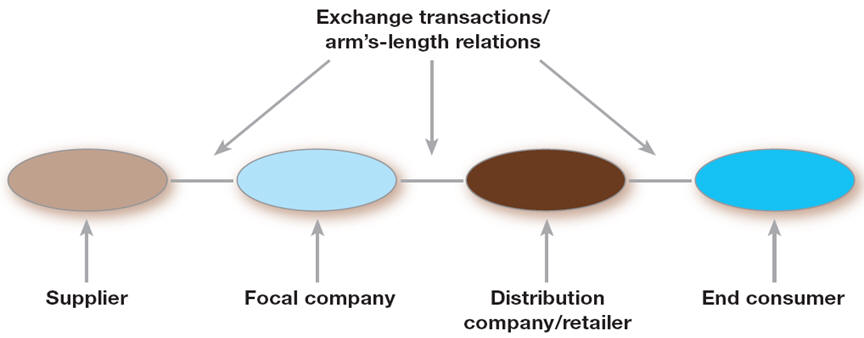

It is helpful to begin by identifying the

characteristics of the fragmented supply chain: different

organizations operating on a contract-by-contract basis, with little

overarching co-ordination (see figure below).

The external supply chain

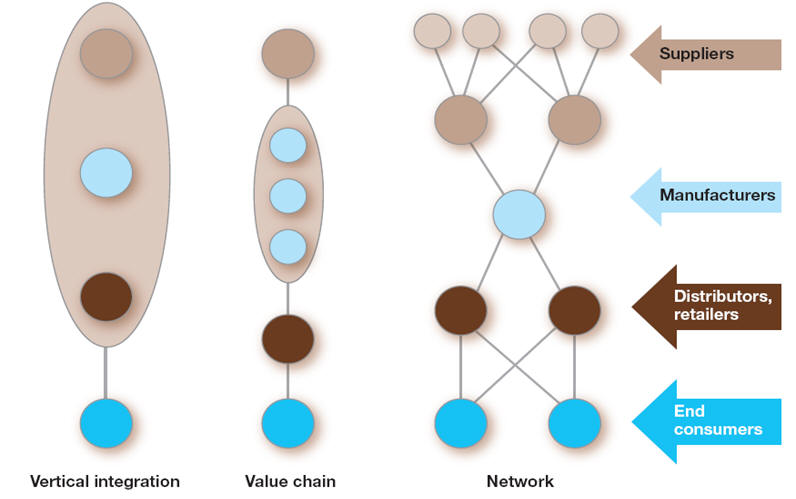

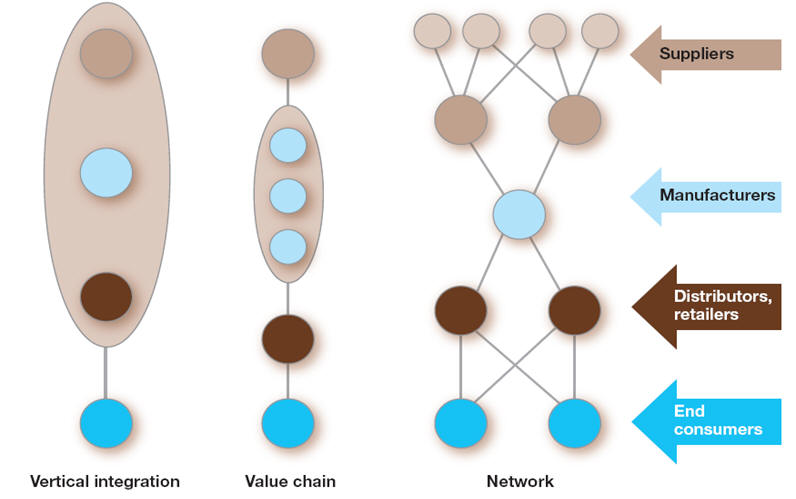

Vertical integration overcomes this fragmented

process, in that the organization exerts control over every phase.

However, internalization involves huge investment and costs. The

Ford Motor Company is often cited as an example. The newer network

approach is more streamline than the fragmented supply chain, and

benefits from flexibility which the vertically integrated operation

cannot match. The network consists of different organizations, but

they are working co-operatively, sharing information and maintaining

close ties. When circumstances of customer requirements change, the

organization can respond with a new network configuration. The

internet permits networks to be coordinated globally.

|

Make or buy decisions

in context (page 366)

Look again at the

sourcing options presented in Figure 10.3, reproduced alongside.

Which companies, in terms of national and corporate culture, are

likely to choose which option(s), and why? The companies may be

either types of firms or real ones.

|

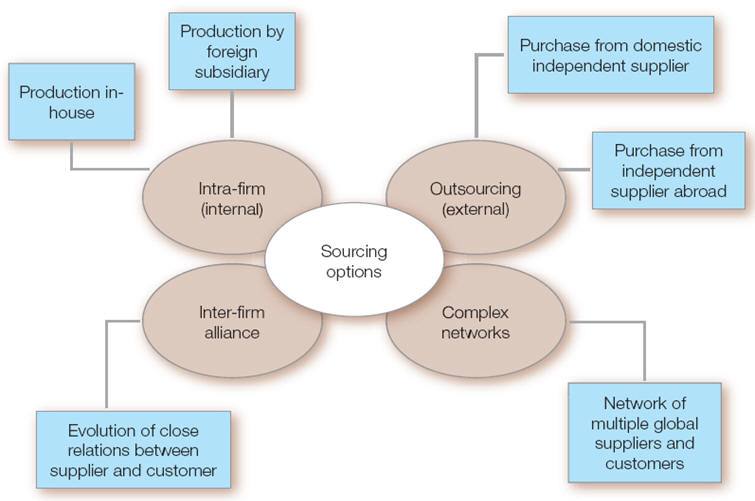

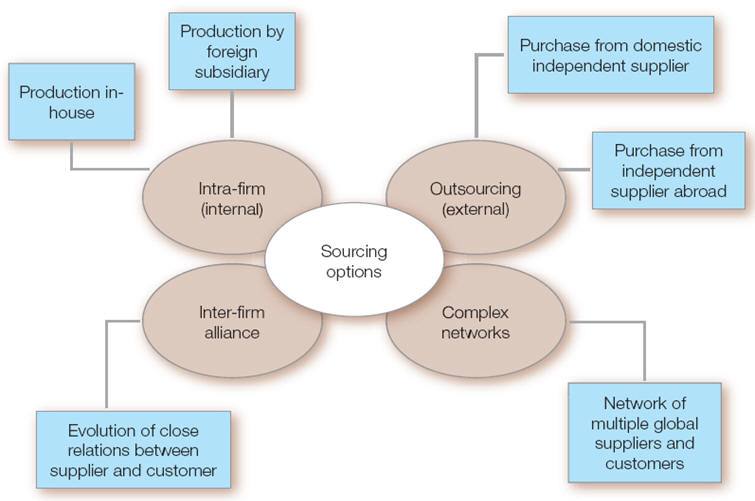

To "make" or "buy" are not the simple

alternatives they might seem. Some firms see purchasing from an external

source as the sole alternative to making a product "in-house". However,

close relations between the suppliers and the customers, through

inter-firm alliances and networks, produce more integrated supply chains

and the blurring of organizational boundaries.

This figure covers 4 broad approaches to

'make-or-buy' decisions:

Intra-firm (internal)

– This approach is

that of the vertically integrated firm. Ford has a history of this

approach, although no longer pursues this strategy. US firms in this

group are likely to be ethnocentric. Unilever, which is more

polycentric, is historically in this category (see CS 7.1)

Outsourcing (external)

– This represents

the opposite approach to the first one, in that the firm contracts

at arm’s length with suppliers. Many firms which have a culture of

self-sufficiency and internalization see this as the logical

alternative – moving from one extreme to the other. Many American

companies have gone over to this approach. An example cited is

Boeing.

Inter-firm alliance

– This is one of the two

approaches which rely on relational ties, rather than purely

transaction-based ties. Japanese companies are noted for this

approach, but, as has been pointed out, inter-firm alliances have

tended to lead to complacency and inefficiency, leading executives

to seek more advantageous deals from external suppliers (see CS 7.2

on Nissan).

Complex networks

– This is a more recent

development. It involves flexible links, by which suppliers and

customers can share knowledge, benefiting both. As each is

constantly reacting to changing markets, participants are less

likely to become complacent, for fear that competitors are waiting

to take their place. Car manufacturing is an example, and Bosch is a

firm which can be cited as exemplifying this approach.

|

Sourcing in the era of

globalization (page 370)

In what ways do

sourcing decisions of MNEs exemplify the process of globalization,

and what aspects of sourcing indicate the importance of

localization?

|

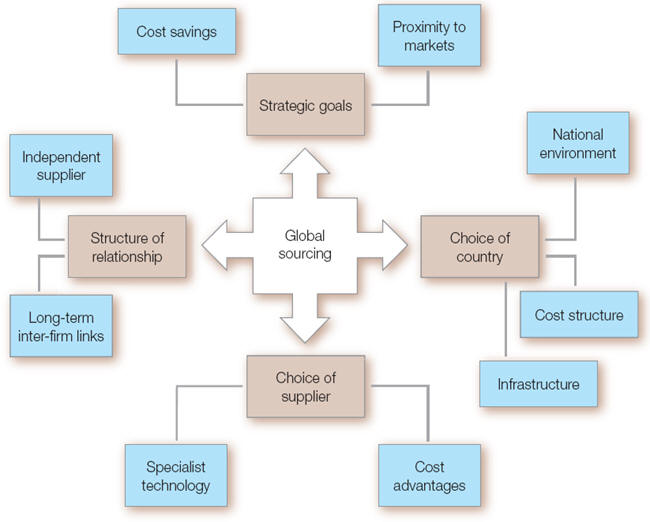

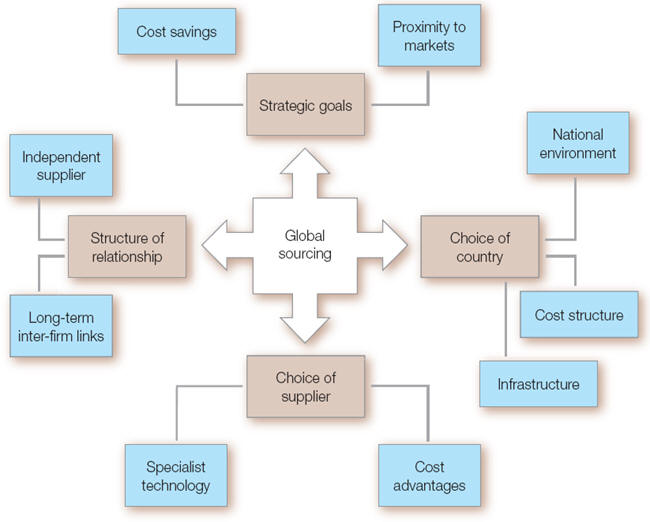

Ways in which globalization

impacts on sourcing decisions:

-

Firms now look at a range of

suppliers globally before deciding on which one

to choose. This is

indicative of global supply chains, with different stages taking

place in different countries.

-

Internet and communications

technology make it possible to do business quickly and cheaply with

supplier firms across the globe, and to keep in touch.

Ways in which localization

plays a role:

-

Individual countries enjoy location

advantages, such as abundant raw materials or low-cost labour, which

have benefited from the global scanning of MNEs.

-

FDI has benefited individual countries, but

each location presents a distinctive national environment, to which

the investor must adapt. The example of Toyota in India is cited.

|

Consumer-driven

manufacturing strategies (page 374)

Outline the ways in

which the following innovations in production are driven by the goal

of consumer satisfaction:

-

lean

production,

-

mass

customization,

-

modular

strategies, and

-

agile

manufacturing.

|

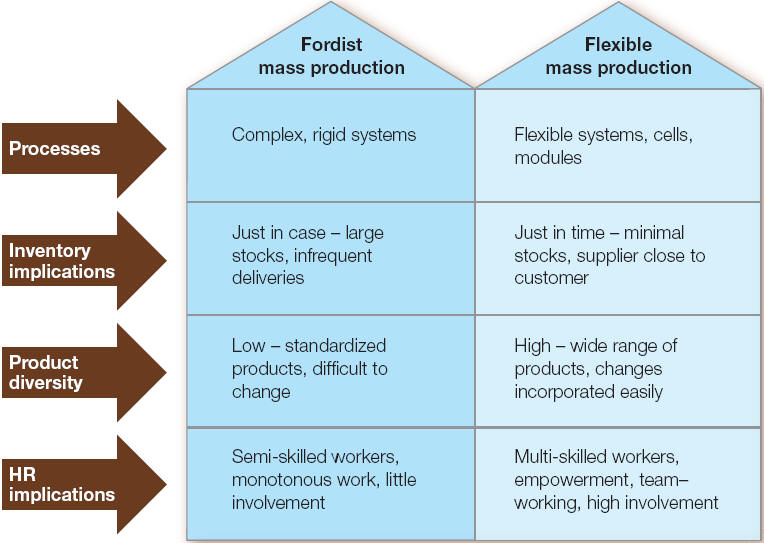

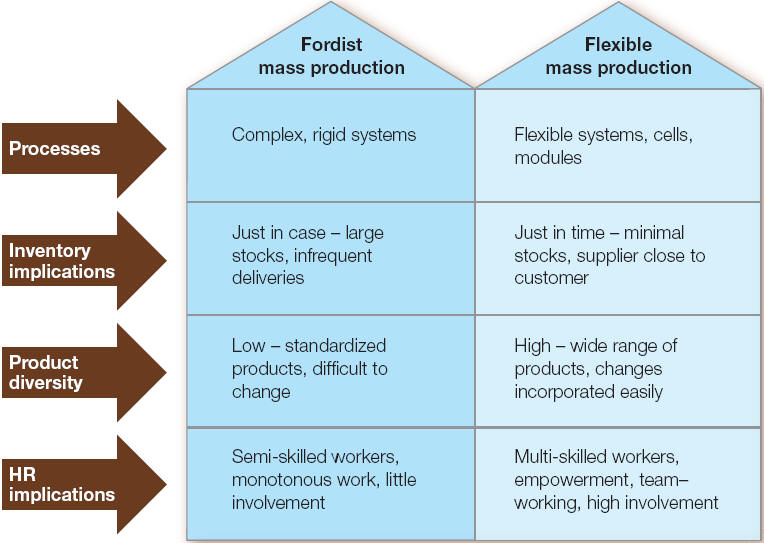

Mass production was once epitomized by the moving

assembly lines at Ford's gigantic River Rouge factory. Called Fordist

mass production, a top-down management system that was very inflexible

in that all the roles and responsibilities were formally allocated and

strictly followed, got eventually replaced by the flexible mass

manufacturing system. The design of the manufacturing process here

includes

Innovations here have been driven by the need to

satisfy consumers in the following ways:

Lean production

– Lean production focuses

on reducing waste, including defects. This improves levels of

quality, and also reduces costs.

Modular strategy

– Modular strategy allows

production costs to be reduced, as a component can be used in

several different products. This means that products can be

customized, while keeping costs low.

Agile manufacturing

– This allows the

manufacturer to respond quickly to changing demand. It is associated

with lean production and JIT (Just-in-Time) systems. The benefits

for the consumer are that the company can respond easily to new

demand and the consumer is not faced with a long wait for the

desired product.

|

The manufacturing

supply chain

(page 375)

In what ways have changes in

manufacturing processes and changes in supplier relationships with

OEMs (Original Equipment Manufacturers) impacted on decisions about

where to manufacture?

|

Many manufacturing processes now envisage the

carrying out of different stages of a complex product in different

locations, to benefit from specific location advantages. |

|

Location

factors in manufacturing

Manufacturers

consider a number of factors in deciding where to manufacture

and which products to manufacture in which location. They

include costs of labor, including skilled labor, proximity to

suppliers, proximity to major markets, level of technology

involved, and the risks to their intellectual property in some

countries. |

|

|

The suppliers of specialist components often have considerable

expertise, and can therefore play a part in innovation and design of new

products from the manufacturer (see the example of Bosch). However, the

extended supply chain has drawbacks, in that it can be inflexible, and

there are risks in delivery and transport over long distances. If a

quality problem is spotted in the assembly of a final product, the

entire operation could be jeopardized as the firm awaits new components

(which could be coming from a company thousands of kilometers away).

Lean production systems rely on close collaboration between

organizations in the supply chain. Suppliers are often in the immediate

vicinity of customer.

As this chapter has shown, Japanese car

manufacturers rely on this type of relationship, but it can be difficult

to duplicate in other countries. Many manufacturers choose to make

high-value products in their home countries, and make low-value products

in foreign low-cost locations. Some companies have prioritized the

guarding of core competencies, and have been reluctant to outsource.

These companies tend to incur high costs if they are located in

developed economies, but many feel that their reputation for quality

justifies this approach. Germany, a high-cost economy, is still a strong

manufacturing country, valuing its high-quality engineering, although

many Germany companies now manufacture globally. This is an indication

of the need to formulate a global strategy on what activities to carry

out where, in seeking competitive advantage.

|

Quality in the

competitive environment

(page 382)

|

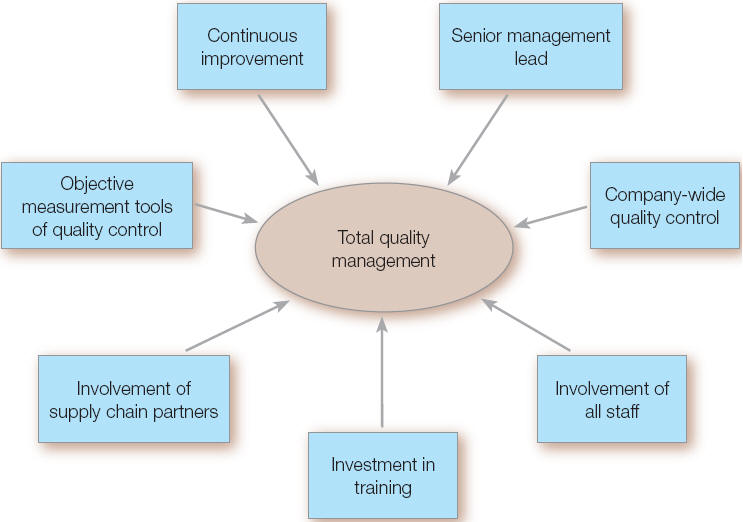

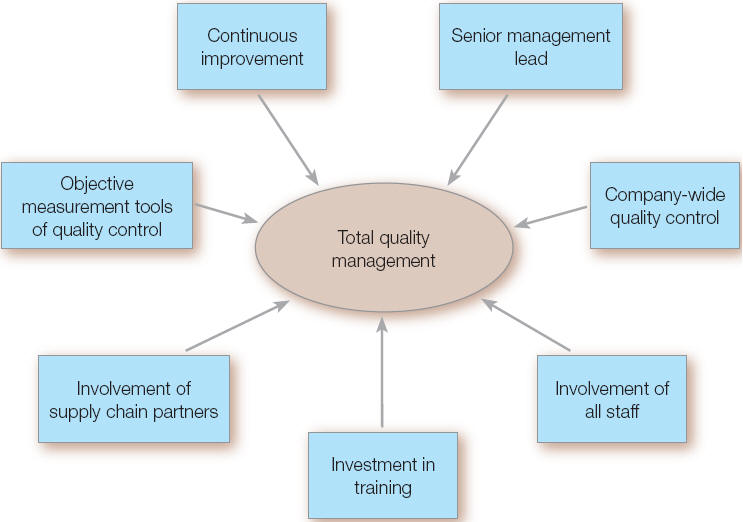

Quality management has evolved

from a functional approach to a broader management philosophy, which

involves the entire organization and supply chain.

Total quality management (TQM)

is the approach to quality that commits the entire organization to

continuous improvement principles and extends to supply chain patterns.

Six sigma is an approach to

quality management that analyses and seeks to improve performance using

a variety of quality measurement tools in order to eliminate defects and

reduce costs. |

|

|

ISO 9000 standards too provide a means for

companies to apply and meet internationally recognized quality

standards.

Price competition has become fierce, and is a

major consideration in many product areas, as products become

standardized or ‘commoditized’. The basic mobile phone is an example.

Although consumers expect quality, they, like manufacturers, are aware

that quality is not an absolute concept. Expectations of quality and

durability vary according to the price of the product. However,

consumers do expect the product to perform as described, to be without

defects and to stand up to reasonable use. Quality systems such as Six

Sigma focus on cost reductions through the elimination of waste. This

approach accords with satisfying consumers that quality is not

sacrificed in mass-produced products.

The strongest growing markets at present are in

the large emerging economies such as China and India. In both countries,

cost is a primary criterion of consumers. China’s manufacturing strength

is well known, but India is now catching up in manufacturing. Quality

management systems are sometimes difficult to operate in developing

countries. An issue is the responsibility placed on individual workers,

which is entailed in continuous improvement systems. In countries of

large power distance, this type of approach is difficult to implement.

China manufactures more toys than any other country, mainly through

production under license for Western markets. Chinese toys have suffered

many setbacks due to poor quality, and brand owners have been criticized

by consumers, concerned about possible harm to children from poor

materials, poor design and defects.

|

Transport and

globalization (page 389)

In what respects

has transport been a facilitator of globalization? What are the

impacts, on both exporting and importing countries, of the huge

variations in transport infrastructure, and associated costs, in

today's world?

|

Transport as a facilitator of

globalization

The single biggest influence on

globalization in transport is probably the container ship (pictured on

the cover of this book) which reduced costs and improved safety.

Globalization is associated with the extended supply chain,

incorporating ports, rail and road. As the IT for managing these

movements improved, companies were able to link the different stages in

the supply chain together. The costs of transport dropped dramatically,

and as a result, shipping mass-produced products from ports in China to

Western markets became commonplace.

|

|

|

Impacts

of the variations in transport infrastructure

Traditional ports must be adapted to take

container ships, and the new superships need extra wide berths, which

require further substantial investment. China has invested heavily in

huge container ports able to handle the new container ships which export

its goods. However, China is the exception. Port infrastructure varies

enormously around the world: the sums involved in funding are huge; the

timescale is long, and in many places, planning issues make it difficult

to bring such projects to completion. Importing countries therefore vary

widely in their ability to handle container ships. Poor road and rail

networks in many countries hamper the movement of goods, and also add to

costs. You might also consider the recent issue of piracy, mainly off

the coast of Somalia. In January 2009, the Chinese government sent its

own naval vessels to the area to protect shipping. Increased incidence

of piracy, along with rising insurance costs, could lead companies to

reconsider overland routes.

|

Rethinking

supply chains

(page 389)

Inflexible

vertically integrated supply chains gave way to more flexible, less

costly alternatives. Global sourcing also offers opportunities to

reduce costs. However, the changing environment and changing markets

are causing firms to rethink supply chain strategies. What specific

factors would you highlight as important in today's environment, and

what strategic responses would you recommend? Give examples from

different sectors.

|

The rethinking on supply chains can be prompted by

a number of factors. Indeed, companies should be constantly rethinking

supply chains. Some that might be mentioned with relevance to today’s

environment:

-

Changing security situation and political

instability in key countries in the supply chain. Also, particular

regions in a country may be more volatile than others. India is an

example, with considerable variation between regions. Companies

contemplating FDI in manufacturing in India must take these risks

into account.

-

The risk of insurgency and terrorist attacks

is more prevalent in some regions than in others. The extraction

industries in Africa are examples.

-

Financial and exchange risk are growing

factors in today’s volatile global financial environment.

-

Economic downturn can mean that supplier and

service companies face possible closure. A firm which depends on a

particular supplier could find that its future is in jeopardy.

Having an alternative supplier in mind is a possibility, but all

could be suffering from a generalized downturn. Many MNEs might

consider taking some key processes back in-house, which had been

outsourced in the past.

-

Transport can become problematic. Piracy

(mentioned above) can affect shipping, and has become a growing

problem of the coast of Somalia. Road and rail links are also

subject to change.

|

-

What challenges are posed by differing cultural environments

in quality management? Give examples.

As

manufacturing and supply chains spread to a wider range of developing and

transitional economies, differing levels of economic and technological

development become issues. These are linked to the cultural environment in

each case: a country in the early stages of industrialization, where most

people are still engaged in agriculture, differs from a more industrialized

economy, in that family ties and kinship values are likely to be stronger

than in industrial economies. In addition, every national culture has its

own historical roots, sense of identity and important symbols which bind

members together. It should also be noted that regions within countries have

distinctive cultures. India is an example: some areas of the country have

become more industrialized than others.

In individualist cultures, employees more readily accept

responsibility for quality systems than in collectivist cultures. In the

latter cultures, which often have large power distance, managers are seen as

the authority figures, and workers in subordinate roles. Workers are not

accustomed to thinking independently about ways to improve quality or

looking critically at processes to see how they can be improved. In many

developing and emerging economies, large power distance is the norm, and

paternalistic management prevails.

A second challenge faced by companies is that of weak

institutional environment, especially in developing countries. Much of the

impetus for quality improvement has come from government or industry-based

regulation in the developed economies. Where these frameworks are weak,

harmful and dangerous products are more likely to enter consumer markets.

Quality problems in China persuaded McDonald’s to take control of its entire

supply chain. The tainted milk scandal in China is another example. In this

case, a New Zealand company found its reputation damaged by association with

a Chinese firm found to be producing contaminated milk.

- Assess the challenges and risks currently

facing logistics management in international operations.

The threat of piracy on

the high seas is now a major worry for shippers and their customers.

Consumers have come to expect an array of imported goods, including food and

durable goods such as electronics, constantly available at reasonable

prices. A number of factors affect supply chains, which pose risk. This is

particularly true in a period of economic downturn.

Following are some of the challenges: