| ART 187 - CERAMICS 2 MAJOLICA PRIMER |

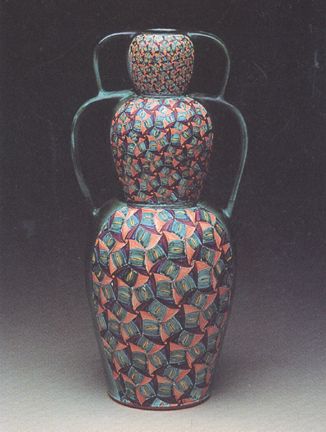

| Majolica refers to a type of pottery characterized by brightly painted designs achieved by the use of oxide washes applied onto an opaque white glaze. Historically, such ware has been earthenware, usually terra cotta, glazed with a lead-tin, opaque, white glaze. Colors result from washes of iron, cobalt, manganese, chrome, copper, vanadium, and other minerals. The origin of majolica is traced to 9th centuty Persian ware, in which the first examples of an opaque white glaze can be found. Early pieces may have been made in an attempt to reproduce the whiteness of the porcelains being brought in from China over the silk route. By the time of the Italian Renaissance, the technique had reached a apex of technical perfection, and the work was exported all over the known world, usuually via the isle of Majorca, thus the name Majolica. The piece at right is a prime example of the painterly skill of the Italian masters of the technique. |

THE FALL OF MAN PLATE, 16TH CENTURY, ITALIAN |

| The version we use here at Glendale Community College involves throwing or handbuilding forms from either the MCR (terra cotta) or the STEVE'S WHITE (white earthenware). After a bisque fire to cone 05, pieces are dipped into the Unleaded Majolica glaze. For technical reasons that will be discussed in the demonstration, the glaze should only be applied by dipping. The glaze is quite stiff, meaning it will not run unless really provoked. The glaze can be brought quite near the footring edge. I use a 3-4 second dip to give a desirable thickness. Be as meticulous as possible when applying the glaze to cause fewer application flaws. Such flaws are difficult to correct. After drying, which should occur within one minute, a design can be painted on using food colors diluted with water. An advantage of this is that the food color will burn away, and not interfere with color application. You can change your mind by using a different food color to paint a revised pattern. Next, washes of the mineral oxides are applied by brushing, sponging, stippling, stenciling, spraying, etc. Practice on a test tile first to find the right amount of pigment necessary to achieve the color desired. Unfortunately, the colors vary greatly in strength, so each color will behave differently. Here is a list of the most common mineral oxides, and their resultant colors: |

| COBALT COPPER IRON MANGANESE CHROME RUTILE (Iron + Titanium) VANADIUM |

blue to blue-violet aqua blue-green amber brown to rust black eggplant-purplish brown bright green (USE THINLY!) mat golden brown (USE THINLY!) yellows |

| A big advantage of doing Majolica is that at this lower temperature, more colors are possible than in a high temperature firing. For this purpose, the simplest method is to purchase commercially available underglazes from a company such as Duncan. Available at the College Bookstore, the EZ Underglazes made by Duncan are quite usable as pigments to paint on the Majolica glaze. Thin the EZ Underglazes with water, approximately 50%-50%, to obtain washes that can be used in combination with the more traditional oxides listed above. EZ colors can be mixed with each other, and with the oxides to create beautifully shaded pigments. Experiment! Colors can be layered in painting also which adds depth and nuance to the work. Remember to consider not only hue when thinking about color choices, but also that value is equally important. Of course, any area you do not paint will remain white, and this should be utilized. Outlining pale areas with a dark value, not necessarily black, will add impact to your design. The most boring designs are inevitably those where all hues fall in the midrange, or those where much too much white is left. Wax resist can be employed as well as sgraffito, scratching through colors to reveal the white glaze below. Pigments can be sprayed over stencils. Use your imagination to think of ways to apply the color. |

VERDE RAMINO Vase, 24"ht, Majolica BY ROBERT KIBLER |

| When all desired color has been applied, the ware is fired once again to cone 05 in an oxidizing atmosphere (electric kilns preferred). After this second firing, the ware is ready to use. Since there is no lead in the Majolica glaze, it is safe for food use. Avoid the microwave and the oven in heating the ware, especially if the pot is cold. I consider Majolica to be best used for serving and dining, and not for use as cooking pots. TROUBLESHOOTING: 1. Fired glaze has 'white spots' in it. Probable cause is glaze applied too thickly, or the ware fired with too long a 'soak.' Another common cause is that the surface of the piece was too rough, and needed to be burnished after trimming to remove the 'grog marks' left by the trimming tool. 2. Glaze 'crawls' over certain areas. Probable cause is too abrupt a change in form. Where a footring meets a bowl, for example, the area should be curved, not angular. Wherever your form changes direction abruptly, curve the juncture. Crawling can also result from applying the glaze too thickly, or applying the colors too thickly, especially the EZ colors. 3. Glaze 'shivers off' during cooling. Cause is that the edges of the form are too sharp or thin. All edges should be rounded. 4. Color looks very dark, even metallic. Color has been applied too thickly. 5. Color areas are mat. Color has been applied too thickly. 6. Color areas are weak, washed out. Color has been applied too thinly. 7. Colors have run, bled. Glaze application was too thick, or kiln was seriously overfired. 8. Colors are smudged. Colors were touched and smeared prior to firing. |